This range is designed for installation over flange joints to prevent injury and damage in the event of a hazardous spray out.

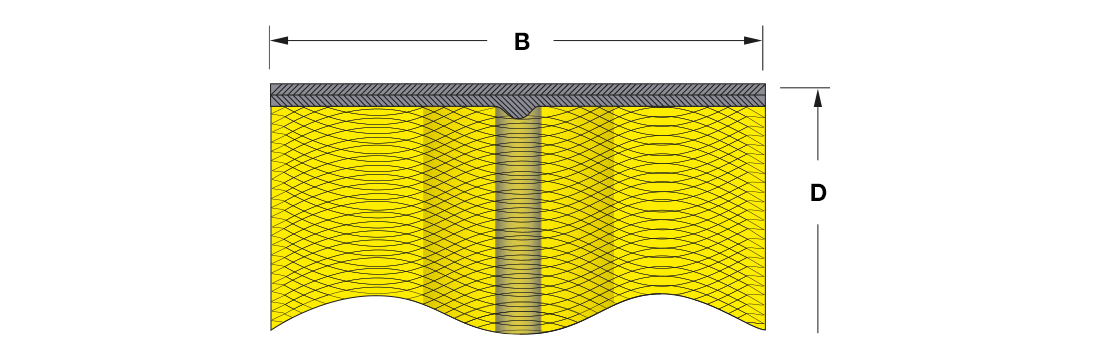

Steel Rings SRM 3600 are used for high temperature and/or pressure applications when PP spray shields are unsuitable for the design conditions.

Stainless steel spray shields in ASTM 316 are suitable for maximum operating

temperature of 1100 °C and maximum operating pressures of 240 bar.

Stainless steel ASTM 316 for high temperature resistance.

Also available: DN 10 up to DN 1.000

Material: Stainless steel ASTM 316

| Flange | 150 lbs | 300 lbs | 400 lbs | 600 lbs | D mm | D Inch | B | Reference No. | Bookmark |

|---|

| ANSI .1/2" | √ | 89.0 | 3.1/2" | 50.0 | SRM-ANSI .1/2" - 150 | ||||

|---|---|---|---|---|---|---|---|---|---|

| ANSI .1/2" | √ | √ | √ | 95.0 | 3.3/4" | 50.0 | SRM-ANSI .1/2" - 300-600 | ||

| ANSI .3/4" | √ | 99.0 | 3.7/8" | 50.0 | SRM-ANSI .3/4" - 150 | ||||

| ANSI .3/4" | √ | √ | √ | 117.0 | 4.5/8" | 50.0 | SRM-ANSI .3/4" - 300-600 | ||

| ANSI 1." | √ | 108.0 | 4.1/4" | 50.0 | SRM-ANSI 1." - 150 | ||||

| ANSI 1." | √ | √ | √ | 124.0 | 4.7/8" | 50.0 | SRM-ANSI 1." - 300-600 | ||

| ANSI 1.1/4" | √ | 117.0 | 4.5/8" | 50.0 | SRM-ANSI 1.1/4" - 150 | ||||

| ANSI 1.1/4" | √ | √ | √ | 133.0 | 5.1/4" | 50.0 | SRM-ANSI 1.1/4" - 300-600 | ||

| ANSI 1.1/2" | √ | 127.0 | 5." | 50.0 | SRM-ANSI 1.1/2" - 150 | ||||

| ANSI 1.1/2" | √ | √ | √ | 155.0 | 6.1/8" | 50.0 | SRM-ANSI 1.1/2" - 300-600 | ||

| ANSI 2." | √ | 152.0 | 6." | 50.0 | SRM-ANSI 2." - 150 | ||||

| ANSI 2." | √ | √ | √ | 165.0 | 6.1/2" | 50.0 | SRM-ANSI 2." - 300-600 | ||

| ANSI 2.1/2" | √ | 178.0 | 7." | 50.0 | SRM-ANSI 2.1/2" - 150 | ||||

| ANSI 2.1/2" | √ | √ | √ | 191.0 | 7.1/2" | 50.0 | SRM-ANSI 2.1/2" - 300-600 | ||

| ANSI 3." | √ | 191.0 | 7.1/2" | 50.0 | SRM-ANSI 3." - 150 | ||||

| ANSI 3." | √ | √ | √ | 210.0 | 8.1/4" | 50.0 | SRM-ANSI 3." - 300-600 | ||

| ANSI 3.1/2" | √ | 216.0 | 8.1/2" | 50.0 | SRM-ANSI 3.1/2" - 150 | ||||

| ANSI 3.1/2" | √ | √ | √ | 229.0 | 9." | 50.0 | SRM-ANSI 3.1/2" - 300-600 | ||

| ANSI 4." | √ | 229.0 | 9." | 50.0 | SRM-ANSI 4." - 150 | ||||

| ANSI 4." | √ | √ | 254.0 | 10." | 50.0 | SRM-ANSI 4." - 300-400 | |||

| ANSI 4." | √ | 273.0 | 10.3/4" | 50.0 | SRM-ANSI 4." - 600 | ||||

| ANSI 5." | √ | 254.0 | 10." | 50.0 | SRM-ANSI 5." - 150 | ||||

| ANSI 5." | √ | √ | 280.0 | 11." | 50.0 | SRM-ANSI 5." - 300-400 | |||

| ANSI 5." | √ | 330.0 | 13." | 50.0 | SRM-ANSI 5." - 600 | ||||

| ANSI 6." | √ | 280.0 | 11." | 50.0 | SRM-ANSI 6." - 150 | ||||

| ANSI 6." | √ | √ | 318.0 | 12.1/2" | 50.0 | SRM-ANSI 6." - 300-400 | |||

| ANSI 6." | √ | 356.0 | 14." | 50.0 | SRM-ANSI 6." - 600 | ||||

| ANSI 8." | √ | 343.0 | 13.1/2" | 50.0 | SRM-ANSI 8." - 150 | ||||

| ANSI 8." | √ | √ | 381.0 | 15." | 50.0 | SRM-ANSI 8." - 300-400 | |||

| ANSI 8." | √ | 419.0 | 16.1/2" | 50.0 | SRM-ANSI 8." - 600 | ||||

| ANSI 10." | √ | 406.0 | 16." | 50.0 | SRM-ANSI 10." - 150 | ||||

| ANSI 10." | √ | √ | 445.0 | 17.1/2" | 50.0 | SRM-ANSI 10." - 300-400 | |||

| ANSI 10." | √ | 508.0 | 20." | 50.0 | SRM-ANSI 10." - 600 | ||||

| ANSI 12." | √ | 483.0 | 19." | 50.0 | SRM-ANSI 12." - 150 | ||||

| ANSI 12." | √ | √ | 521.0 | 20.1/2" | 50.0 | SRM-ANSI 12." - 300-400 | |||

| ANSI 12." | √ | 559.0 | 22." | 50.0 | SRM-ANSI 12." - 600 | ||||

| ANSI 14." | √ | 533.0 | 21." | 50.0 | SRM-ANSI 14." - 150 | ||||

| ANSI 14." | √ | √ | 584.0 | 23." | 50.0 | SRM-ANSI 14." - 300-400 | |||

| ANSI 14." | √ | 603.0 | 23.3/4" | 50.0 | SRM-ANSI 14." - 600 | ||||

| ANSI 16." | √ | 597.0 | 23.1/2" | 50.0 | SRM-ANSI 16." - 150 | ||||

| ANSI 16." | √ | √ | 648.0 | 25.1/2" | 50.0 | SRM-ANSI 16." - 300-400 | |||

| ANSI 16." | √ | 686.0 | 27." | 50.0 | SRM-ANSI 16." - 600 | ||||

| ANSI 18." | √ | 635.0 | 25." | 50.0 | SRM-ANSI 18." - 150 | ||||

| ANSI 18." | √ | √ | 711.0 | 28." | 50.0 | SRM-ANSI 18." - 300-400 | |||

| ANSI 18." | √ | 743.0 | 29.1/4" | 50.0 | SRM-ANSI 18." - 600 | ||||

| ANSI 20." | √ | 699.0 | 27.1/2" | 50.0 | SRM-ANSI 20." - 150 | ||||

| ANSI 20." | √ | √ | 775.0 | 30.1/2" | 50.0 | SRM-ANSI 20." - 300-400 | |||

| ANSI 20." | √ | 813.0 | 32." | 50.0 | SRM-ANSI 20." - 600 | ||||

| ANSI 24." | √ | 813.0 | 32." | 50.0 | SRM-ANSI 24." - 150 | ||||

| ANSI 24." | √ | √ | 914.0 | 36." | 50.0 | SRM-ANSI 24." - 300-400 | |||

| ANSI 24." | √ | 940.0 | 37." | 50.0 | SRM-ANSI 24." - 600 |

| Flange | 150 lbs | 300 lbs | 400 lbs | 600 lbs | D mm | D Inch | B | Reference No. |

|---|

| ANSI .1/2" | √ | 89.0 | 3.1/2" | 50.0 | SRM-ANSI .1/2" - 150 | ||||

|---|---|---|---|---|---|---|---|---|---|

| ANSI .1/2" | √ | √ | √ | 95.0 | 3.3/4" | 50.0 | SRM-ANSI .1/2" - 300-600 | ||

| ANSI .3/4" | √ | 99.0 | 3.7/8" | 50.0 | SRM-ANSI .3/4" - 150 | ||||

| ANSI .3/4" | √ | √ | √ | 117.0 | 4.5/8" | 50.0 | SRM-ANSI .3/4" - 300-600 | ||

| ANSI 1." | √ | 108.0 | 4.1/4" | 50.0 | SRM-ANSI 1." - 150 | ||||

| ANSI 1." | √ | √ | √ | 124.0 | 4.7/8" | 50.0 | SRM-ANSI 1." - 300-600 | ||

| ANSI 1.1/4" | √ | 117.0 | 4.5/8" | 50.0 | SRM-ANSI 1.1/4" - 150 | ||||

| ANSI 1.1/4" | √ | √ | √ | 133.0 | 5.1/4" | 50.0 | SRM-ANSI 1.1/4" - 300-600 | ||

| ANSI 1.1/2" | √ | 127.0 | 5." | 50.0 | SRM-ANSI 1.1/2" - 150 | ||||

| ANSI 1.1/2" | √ | √ | √ | 155.0 | 6.1/8" | 50.0 | SRM-ANSI 1.1/2" - 300-600 | ||

| ANSI 2." | √ | 152.0 | 6." | 50.0 | SRM-ANSI 2." - 150 | ||||

| ANSI 2." | √ | √ | √ | 165.0 | 6.1/2" | 50.0 | SRM-ANSI 2." - 300-600 | ||

| ANSI 2.1/2" | √ | 178.0 | 7." | 50.0 | SRM-ANSI 2.1/2" - 150 | ||||

| ANSI 2.1/2" | √ | √ | √ | 191.0 | 7.1/2" | 50.0 | SRM-ANSI 2.1/2" - 300-600 | ||

| ANSI 3." | √ | 191.0 | 7.1/2" | 50.0 | SRM-ANSI 3." - 150 | ||||

| ANSI 3." | √ | √ | √ | 210.0 | 8.1/4" | 50.0 | SRM-ANSI 3." - 300-600 | ||

| ANSI 3.1/2" | √ | 216.0 | 8.1/2" | 50.0 | SRM-ANSI 3.1/2" - 150 | ||||

| ANSI 3.1/2" | √ | √ | √ | 229.0 | 9." | 50.0 | SRM-ANSI 3.1/2" - 300-600 | ||

| ANSI 4." | √ | 229.0 | 9." | 50.0 | SRM-ANSI 4." - 150 | ||||

| ANSI 4." | √ | √ | 254.0 | 10." | 50.0 | SRM-ANSI 4." - 300-400 | |||

| ANSI 4." | √ | 273.0 | 10.3/4" | 50.0 | SRM-ANSI 4." - 600 | ||||

| ANSI 5." | √ | 254.0 | 10." | 50.0 | SRM-ANSI 5." - 150 | ||||

| ANSI 5." | √ | √ | 280.0 | 11." | 50.0 | SRM-ANSI 5." - 300-400 | |||

| ANSI 5." | √ | 330.0 | 13." | 50.0 | SRM-ANSI 5." - 600 | ||||

| ANSI 6." | √ | 280.0 | 11." | 50.0 | SRM-ANSI 6." - 150 | ||||

| ANSI 6." | √ | √ | 318.0 | 12.1/2" | 50.0 | SRM-ANSI 6." - 300-400 | |||

| ANSI 6." | √ | 356.0 | 14." | 50.0 | SRM-ANSI 6." - 600 | ||||

| ANSI 8." | √ | 343.0 | 13.1/2" | 50.0 | SRM-ANSI 8." - 150 | ||||

| ANSI 8." | √ | √ | 381.0 | 15." | 50.0 | SRM-ANSI 8." - 300-400 | |||

| ANSI 8." | √ | 419.0 | 16.1/2" | 50.0 | SRM-ANSI 8." - 600 | ||||

| ANSI 10." | √ | 406.0 | 16." | 50.0 | SRM-ANSI 10." - 150 | ||||

| ANSI 10." | √ | √ | 445.0 | 17.1/2" | 50.0 | SRM-ANSI 10." - 300-400 | |||

| ANSI 10." | √ | 508.0 | 20." | 50.0 | SRM-ANSI 10." - 600 | ||||

| ANSI 12." | √ | 483.0 | 19." | 50.0 | SRM-ANSI 12." - 150 | ||||

| ANSI 12." | √ | √ | 521.0 | 20.1/2" | 50.0 | SRM-ANSI 12." - 300-400 | |||

| ANSI 12." | √ | 559.0 | 22." | 50.0 | SRM-ANSI 12." - 600 | ||||

| ANSI 14." | √ | 533.0 | 21." | 50.0 | SRM-ANSI 14." - 150 | ||||

| ANSI 14." | √ | √ | 584.0 | 23." | 50.0 | SRM-ANSI 14." - 300-400 | |||

| ANSI 14." | √ | 603.0 | 23.3/4" | 50.0 | SRM-ANSI 14." - 600 | ||||

| ANSI 16." | √ | 597.0 | 23.1/2" | 50.0 | SRM-ANSI 16." - 150 | ||||

| ANSI 16." | √ | √ | 648.0 | 25.1/2" | 50.0 | SRM-ANSI 16." - 300-400 | |||

| ANSI 16." | √ | 686.0 | 27." | 50.0 | SRM-ANSI 16." - 600 | ||||

| ANSI 18." | √ | 635.0 | 25." | 50.0 | SRM-ANSI 18." - 150 | ||||

| ANSI 18." | √ | √ | 711.0 | 28." | 50.0 | SRM-ANSI 18." - 300-400 | |||

| ANSI 18." | √ | 743.0 | 29.1/4" | 50.0 | SRM-ANSI 18." - 600 | ||||

| ANSI 20." | √ | 699.0 | 27.1/2" | 50.0 | SRM-ANSI 20." - 150 | ||||

| ANSI 20." | √ | √ | 775.0 | 30.1/2" | 50.0 | SRM-ANSI 20." - 300-400 | |||

| ANSI 20." | √ | 813.0 | 32." | 50.0 | SRM-ANSI 20." - 600 | ||||

| ANSI 24." | √ | 813.0 | 32." | 50.0 | SRM-ANSI 24." - 150 | ||||

| ANSI 24." | √ | √ | 914.0 | 36." | 50.0 | SRM-ANSI 24." - 300-400 | |||

| ANSI 24." | √ | 940.0 | 37." | 50.0 | SRM-ANSI 24." - 600 |

PROTEC products and specifications are subject to improvement and change without notice.

DURA-SAFE® SRM 3600A Individual Productions:

On request we develop and produce individually tailored solutions along with the standard items of this range: If you require additional dimensions, different materials and new colours. We would be pleased to assist you.

Delivery Service:

Orders that arrive before midday can be despatched on the same day, using either our standard service or via a faster service if required.

Ask for free no-obligation samples and more information on our contact form.

We will promptly take care of your request and get in touch with you.

Please click here.

You will finde more details on how we protect you data during the chat session in our privacy policy.

PROTEC meets the most stringent demands of safety and operations reliability. International approvals and certifications such as UL, CSA, VDE, VDA 6.1 and DIN EN ISO 9001: 2015 demonstrate total quality commitment on superior level.

Stay on top of the latest news and upcoming events and event information from PROTEC and its partner. Be the first to know when new products are on the market. Get periodic specials and news delivered directly to your email inbox! You can un-subscribe anytime.

Sign our free newsletter now